Enterprise-Grade Offset & Digital Print Manufacturing

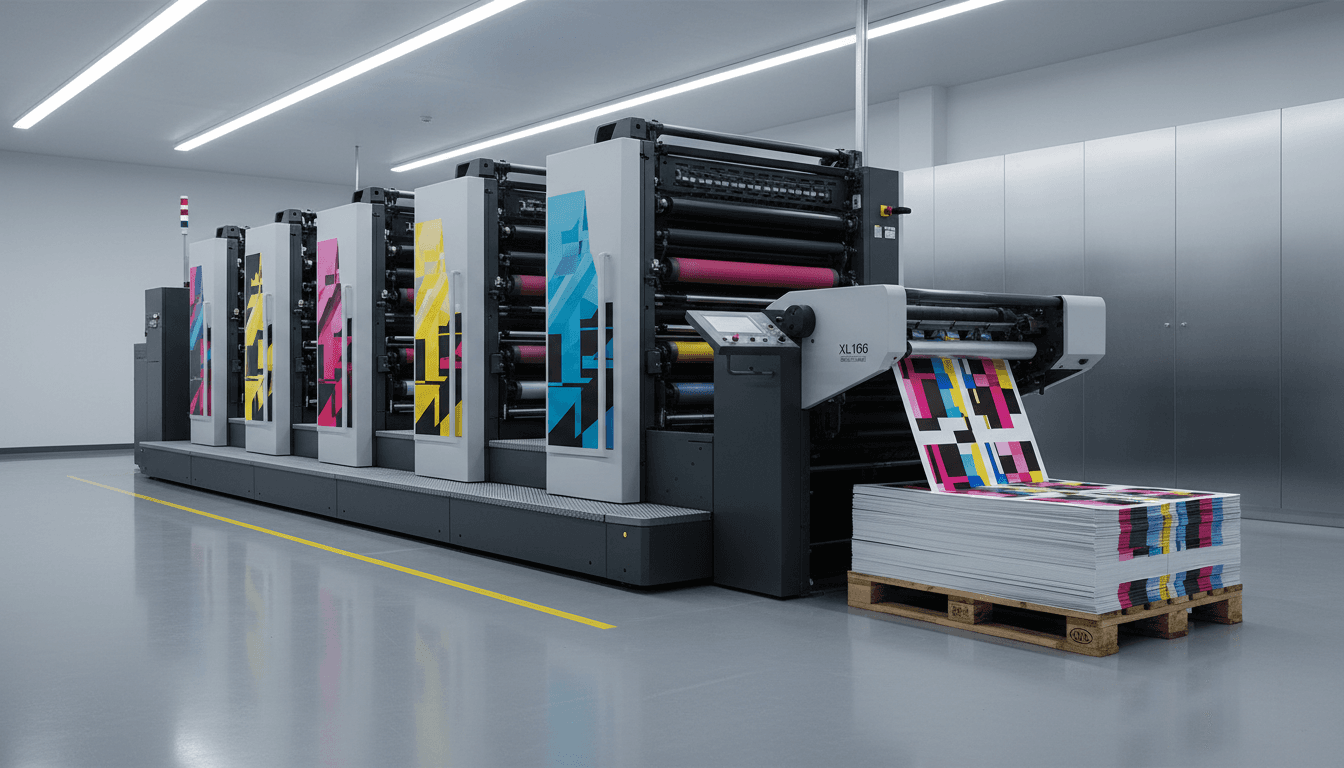

High-volume offset and on-demand digital production for packaging, labels, inserts, and marketing collateral. Our Heidelberg 6-color press technology delivers consistent color accuracy across production runs of any scale — from 500 to 5,000,000 units.

What Sets Our Custom Print Production Apart

Heidelberg 6-Color Offset Press

Industry-leading Heidelberg presses deliver registration accuracy within ±0.1mm and support up to 8-color process printing for Pantone-precise brand reproduction.

On-Demand Digital Production

Variable data printing and short-run digital production enable rapid prototyping, versioning, and market testing without plate charges or minimum commitments.

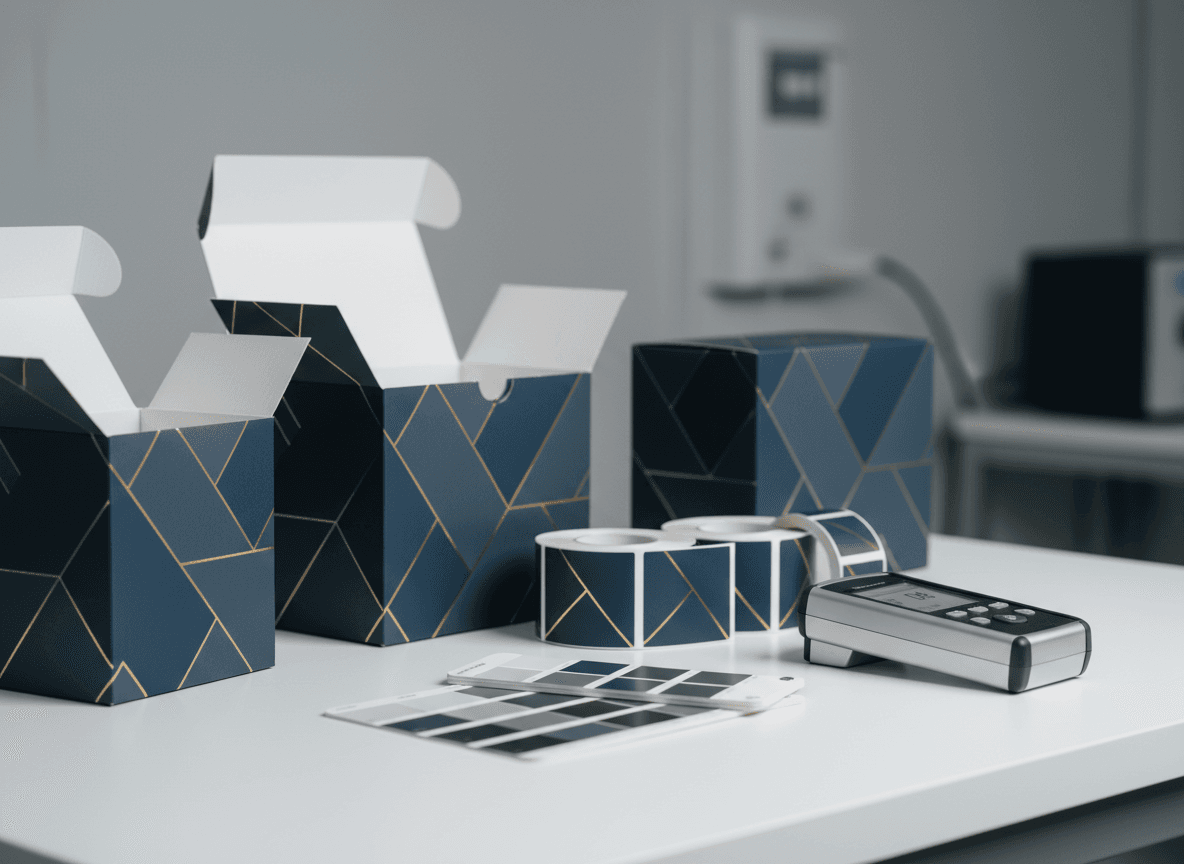

Color Management System

Spectrophotometer-verified color matching ensures Delta E < 2.0 consistency across production runs, with physical proofs provided before every production order.

Gang-Run Scheduling

Intelligent job scheduling groups orders on shared press sheets to reduce per-unit costs by up to 30% without sacrificing quality or turnaround time.

Multi-Substrate Capability

Print on paper, card stock, synthetic films, metallic substrates, and specialty materials — all on the same production line with calibrated color profiles for each.

Technical Specifications

Materials We Work With

- C1S / C2S Coated Paper

- Uncoated Bond & Offset Paper

- SBS & FBB Card Stock

- Corrugated Board (E, B, C flute)

- Synthetic Polypropylene (PP)

- Metallic Foil Board

- Recycled & FSC-Certified Stock

Common Use Cases

- ■Product packaging & retail boxes

- ■Labels & hang tags

- ■Product inserts & instruction manuals

- ■Marketing collateral & brochures

- ■Point-of-sale displays

- ■Catalog & booklet production

National Retail Brand — 2M Unit Packaging Rollout

Challenge

A national retail chain needed to launch new packaging across 400+ store locations within a 6-week window, requiring exact Pantone color matching across multiple substrate types.

Solution

We utilized gang-run scheduling on our Heidelberg 6-color press with spectrophotometer-verified color management. Digital prototyping was used for initial approval, then seamless transition to offset for full-scale production.

Result

All 2 million units were delivered on schedule with Delta E < 1.5 color consistency. The client reduced per-unit print costs by 22% compared to their previous supplier through our gang-run optimization.

2,000,000

Units Produced

ΔE < 1.5

Color Accuracy

22%

Cost Savings

100%

On-Time Delivery

Frequently Asked Questions

What is the minimum order quantity for custom offset printing?

Our minimum order for offset printing is 500 units. For smaller runs or prototyping, we offer digital production with no minimum order requirement. We can help determine the most cost-effective method based on your quantity and specifications.

How do you ensure color consistency across large production runs?

We use spectrophotometer-verified color management with Delta E < 2.0 tolerance. Every production run begins with a physical proof approval, and in-line color monitoring checks consistency throughout the run at regular intervals.

Can I combine offset and digital printing in a single program?

Absolutely. Many enterprise clients use offset for high-volume core SKUs and digital for short-run seasonal variants or regional versions. We manage both production streams under a single program with consistent color calibration across methods.

What file formats do you accept for print production?

We accept press-ready PDF/X-1a and PDF/X-4 files as standard. We also work with Adobe Illustrator (.ai), InDesign packaged files, and high-resolution TIFF/PSD files. Our prepress team provides free file checks before production.

Explore More Capabilities

Specialty Materials

Production on 40+ substrate options including magnetic sheets, vinyl decals, kraft paper, synthetic waterproof materials, metallic foils, and clear films. Each material is tested and matched to your specific application requirements — from outdoor durability to food-safe contact surfaces.

Learn more →Custom Shapes & Premium FinishesDie-Cut & Finishing

Precision die-cutting for custom shapes combined with premium finishing options including UV coating, hot foil stamping, embossing, debossing, spot varnish, and lamination. All finishing processes are executed in-house for quality control and faster turnaround.

Learn more →Banners, Signage & DisplaysLarge Format Production

Wide-format digital and screen printing for banners, trade show displays, point-of-sale signage, vehicle wraps, and architectural graphics. Indoor and outdoor rated materials available with output widths up to 5 meters for maximum visual impact.

Learn more →Industries Using Custom Print Production

You Might Also Be Interested In

Retail & E-Commerce Solutions

Custom packaging, labels, and POS displays for retail brands.

Read more →Consumer Goods & FMCG

High-volume print production for fast-moving consumer goods brands.

Read more →Offset vs. Digital: Enterprise Buyer's Guide

Cost-per-unit crossover, quality differences, and production timelines.

Read more →5 Ways to Reduce Print Costs

Enterprise procurement strategies for optimizing print spend.

Read more →Die-Cut & Finishing

Precision die-cutting, foil stamping, embossing, UV coating, and lamination.

Read more →Specialty Materials

Print on 40+ substrates: magnetic, vinyl, kraft, synthetics, and more.

Read more →Related Resources

Retail & E-Commerce Solutions

Custom packaging, POS displays, and labels for retail brand consistency.

Learn more →Consumer Goods & FMCG

High-volume packaging and labels for fast-moving consumer goods.

Learn more →Offset vs. Digital Printing Guide

When to choose offset and when digital makes more sense for enterprise programs.

Learn more →Ready to Get Started with Custom Print Production?

Tell us about your project requirements and get a custom quote within 24 hours. No minimums on digital production — start with a prototype and scale to millions.